TÜBİTAK MAM has been conducting studies on superalloys since the 1980s. These materials are used in high-priority industries with strategic importance for Turkey, however, almost all of them are imported from foreign countries. One of the most important targets of the MAM Materials Institute is to create the know-how, database and technological infrastructure that will allow the domestic manufacture, repair and maintenance of “steam turbines” and “gas turbines” of especially power plants, and to add these capabilities to Turkish industry.

In this project, for an over-130MW gas turbine operated by EÜAŞ (Electricity Generation Company), sets of blades -1 for 1- were manufactured for each 3rd stage rotor (moving) and stator (fixed) by precision casting technique in compliance with original forms and specifications; and they will be tested for 8.000 hours on a 130MW turbine. The blades will have a design life of 33000 hours. Selection of 3rd stage blades will serve for two basic goals. These blades are at suitable dimensions for casting and their surfaces have aluminized coating. By selecting 3rd stage blades, it was aimed to gain competence in coating technologies in addition to casting technologies.

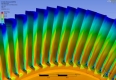

The project partners -TÜBİTAK MAM Materials Institute (ME), Gür Metal, SDM and EÜAŞ- cooperated under the coordination of TÜBİTAK MAM. Also, within the scope of the project, TÜBİTAK MAM ME conducted destructive examinations on the old, used blades provided by EÜAŞ, and determined metallurgical properties. “SDM Engineering Co.” determined and modeled in-turbine conditions by means of sensors.

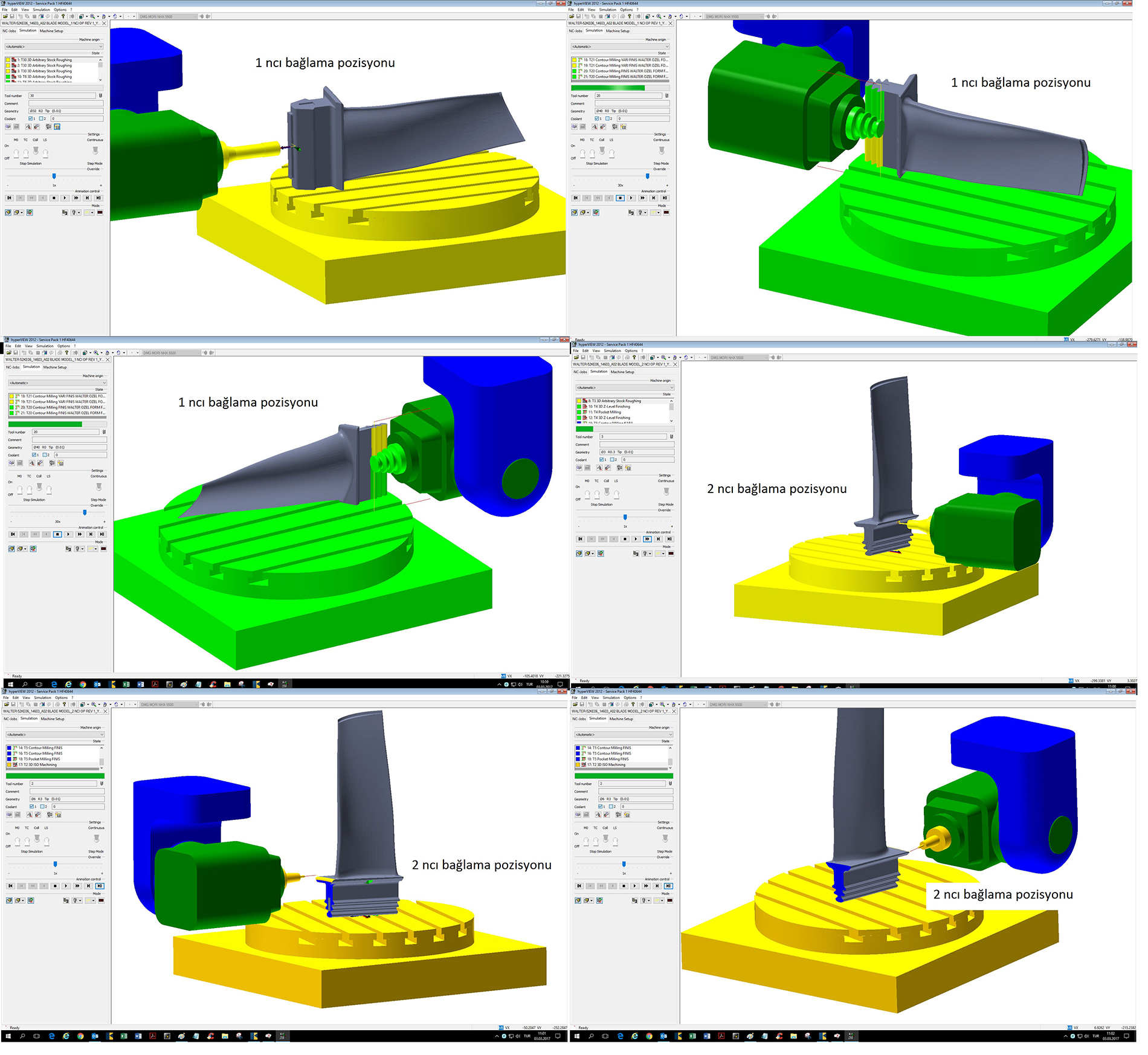

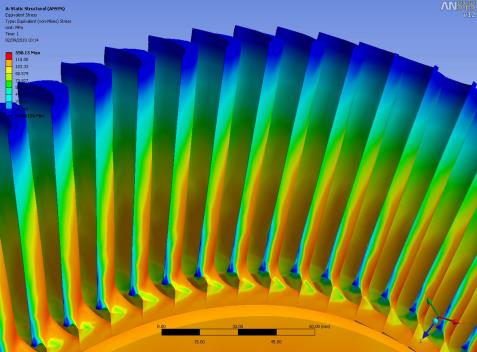

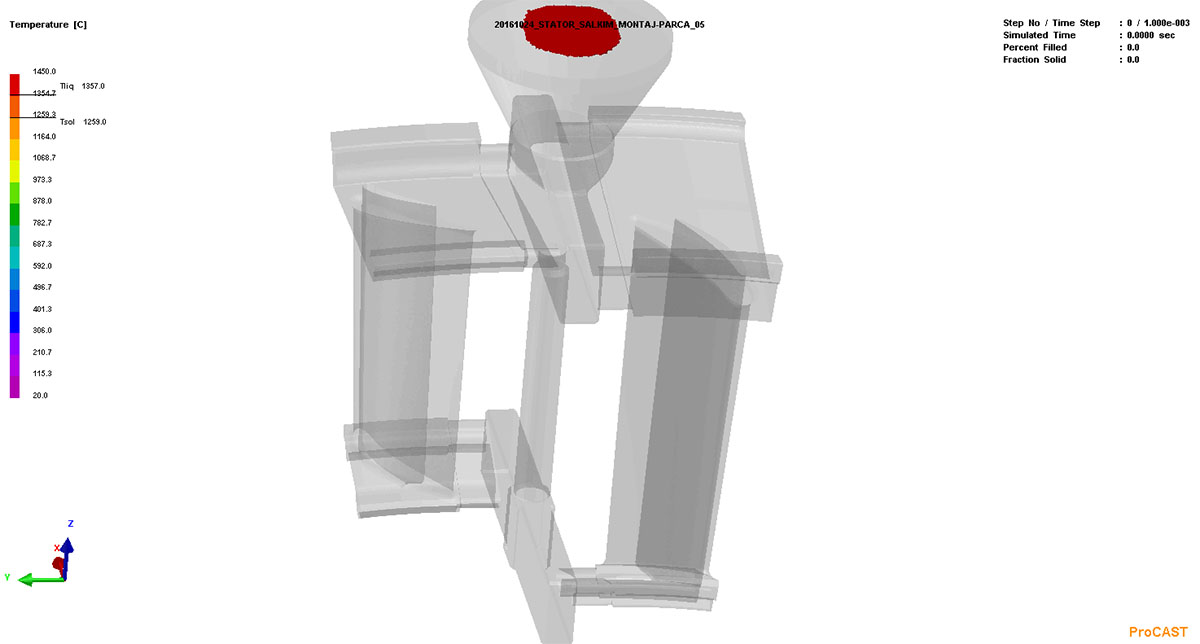

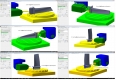

Based on these studies, “Gür Metal” prepared local stress maps of blades, and made mold designs paying attention to stress densities in casting method. The designed molds were developed with casting simulation program and the most suitable casting wax and ceramic molds were modeled. The whole casting process was realized at Gür Metal Company under the supervision of TÜBİTAK MAM. System optimizations of manufacturing methods were made by TÜBİTAK MAM. The cast superalloy blades of gas turbines were subjected to HIP to eliminate possible metallurgical faults caused by casting method.

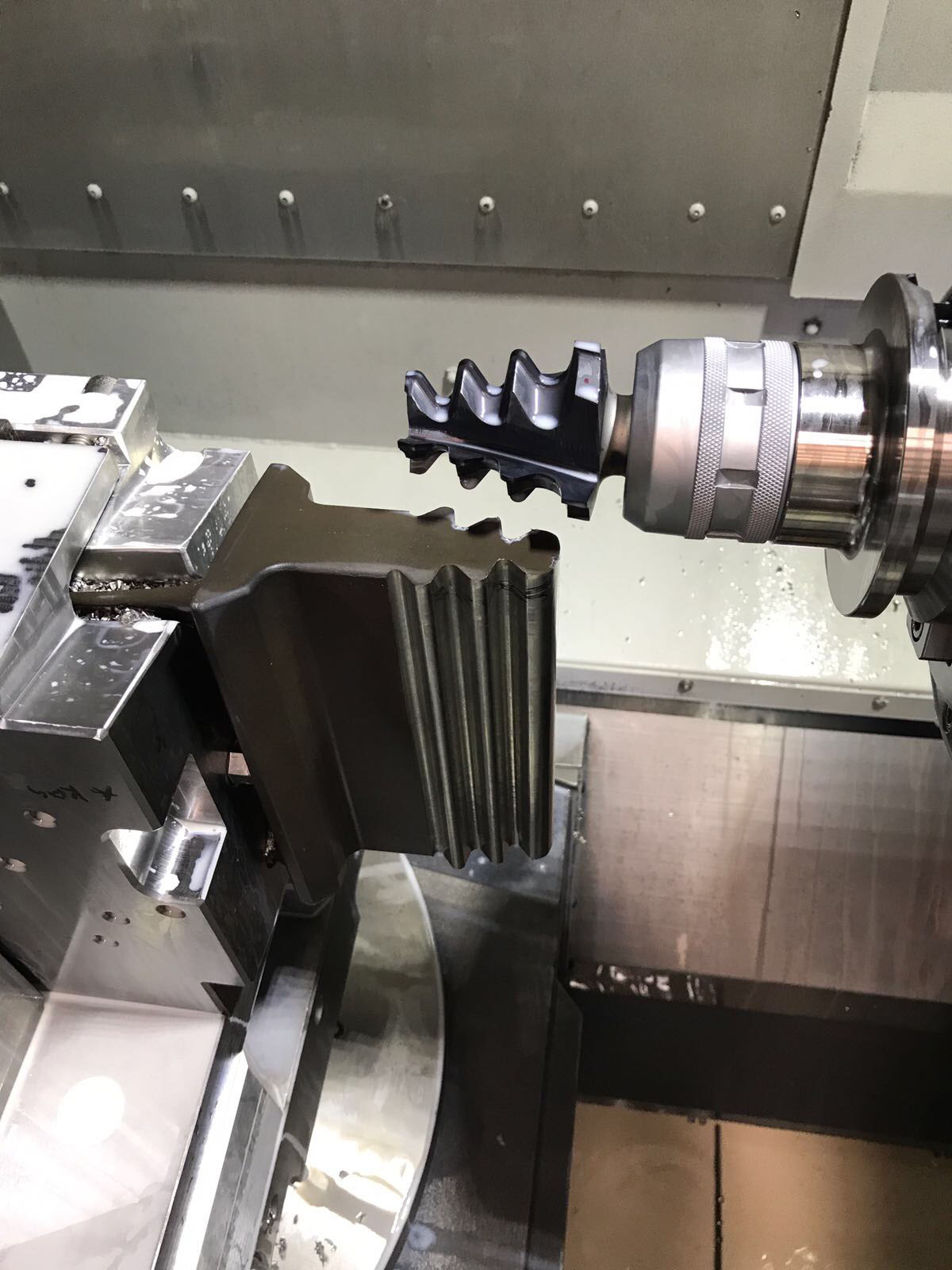

The HIP processes of nickel based superalloys were conducted at TÜBİTAK MAM ME. The blades that were cast were subjected to heat treatment. Then, the blades were put into final form by being processed at “Kaan Makina” under the supervision of TÜBİTAK MAM. R&D studies of the CVD coating were conducted at Middle East Technical University. CVD coating of the blades was made at TÜBİTAK MAM ME. Shot Peening process was implemented at “HMS Makina” under the supervision of TÜBİTAK MAM. Frequency tests were performed at “Novosim” company under the supervision of SDM and TÜBİTAK MAM.

In all process stages, TÜBİTAK MAM allowed the use of its wide range of laboratories, made characterizations with destructive and non-destructive methods and optimized the processes duly at each stage.